After leaving National Cash Register Company in 1960, Wiley Thomas Nickell had an idea. His plan was to build a machine that would print labels. He didn’t want to build another printing press to be marketed to big companies, his idea was for every small company to have a way to print their own labels with their own press and flexographic printing plates of the time.

He designed, built and marketed the Label Imprinter. In the late 1960’s mailing labels had to be produced through a professional printer. Unlike today, each home did not have a computer and a printer. Avery and the return address labels they make were not an option. Every company wanted professional looking envelopes to send their ever important mail with professional, personalized return address labels. Shipping labels were very popular and every product companies produced needed shipping labels as well.

Technology finally caught up to Mr. Nickells mechanical imprinting presses and they were soon replaced by the modern day ink jet and laser printers as well as Thermal Transfer printing devices that were becoming available. Mr. Nickell used his flexographic printing experience to continue printing flexographic pressure sensitive labels. He teamed up with a local Cincinnati company, Comco and purchased a 7″ Label press with die cutting capability to produce pressure sensitive roll labels.

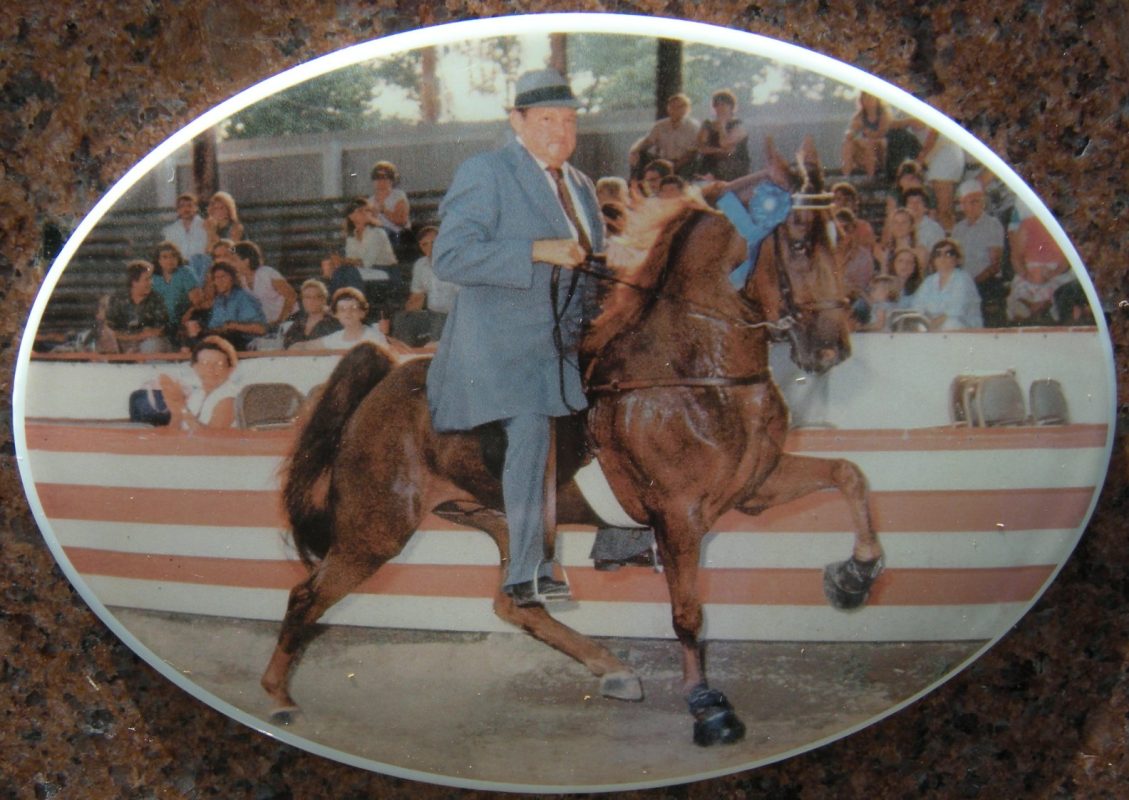

The business has expanded and grown through several locations including an old Dairy Barn on Old State Route 74, in Batavia Ohio he converted to a manufacturing facility. For over 40 years, Wiley Thomas Nickell grew his business and worked with the company into his 80’s.

In 2002 the company was purchased by a local friend to carry on the tradition Mr. Nickell started. New Printing presses were purchased and the business continued to grow. Evolving with the technologies and trends in the pressure sensitive label market. In 2009, WT Nickell Company moved into a new facility just off State Route 32, in Batavia, Ohio. A larger facility was needed to fulfill the demands of our customers and inventory management as well as a climate controlled facility to house a new Digital pressure sensitive Label Press.

Since then we have continued to invest in NEW equipment expanding our capabilities. In 2016 we invested in a NEW HP Indigo 4050. In 2022 we replaced our HP Indigo with a brand new HP Indigo 6000 with an inline coater to print on just about any substrate.

In 2023 we purchased a 13″ Nilpeter Flexographic press with Servo Registration to match the digital press quality but for larger label orders or runs. Time is money and when you have a fast efficient press, you can save A LOT of money and pass the savings on to our customers.